|

MIDWEST CORPORATE & MANUFACTURING

Located approximately 50 miles from Chicago in Grayslake, Illinois is our corporate office and 65,000 square foot manufacturing facility.

Centrally located on the eastern seaboard in Fairmont, NC is another 95,000 square foot manufacturing plant. |

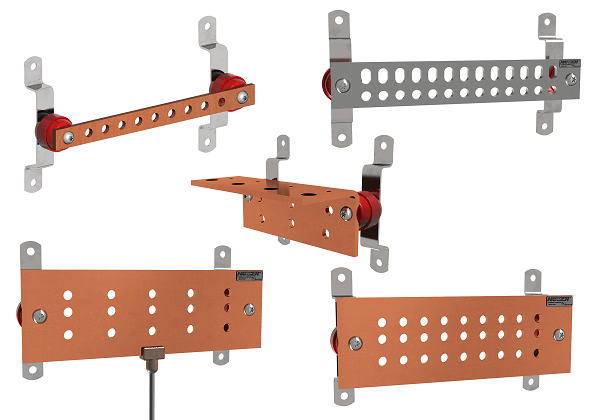

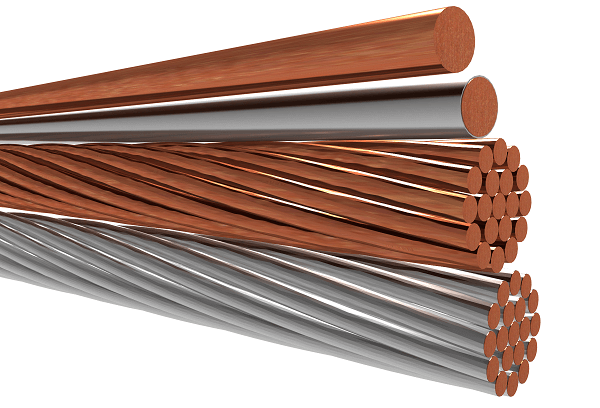

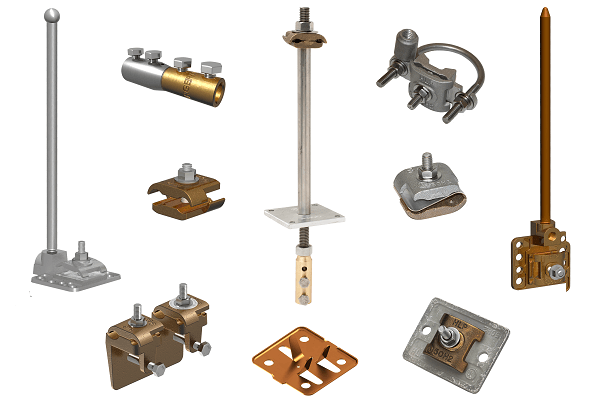

About HargerHarger, a TE Connectivity Company, is a trusted American manufacturer providing comprehensive grounding, exothermic welding, and lightning protection solutions—engineered to support complete project execution from design to installation. With over 65 years of engineering expertise, a strong service culture, and U.S.-based manufacturing facilities in Illinois and North Carolina, Harger delivers high-quality, made-in-the-USA products for critical energy infrastructure. Acquired by TE Connectivity in November 2024, Harger now operates as part of a global technology leader while continuing its legacy of excellence. From grounding and bonding to exothermic welding and lightning protection, Harger offers comprehensive solutions—supported by expert design assistance, hands-on training, and certified installation support—to help build more resilient power networks. |

Call Us: 800-842-7437

Find A Product Rep

Our mission is to provide the best grounding and lightning protection equipment in the world. We will accomplish this by providing the most accurate engineering designs available and supplying the highest quality materials.